An Australian company has secured an exclusive distributorship in the USA for a hempcrete building system it says is cost competitive with traditional construction. Queensland-based HempBLOCK Australia also has begun marketing and selling the bio-based system, made by the French firm Vieille Matériaux, in Australia and New Zealand.

Johan Tijssen, Director at HempBLOCK operations in the USA and Australia, said the extensive research his company has undertaken confirmed conditions are right for entering the U.S. market.

“The residential construction market in the U.S. is huge,” said Tijssen, noting 416,000 single unit residential building permits were issued last year, with 90% timber framed and 10% from concrete masonry. He said HempBLOCK is targeting six key residential construction growth regions in the U.S.

For homes, small buildings

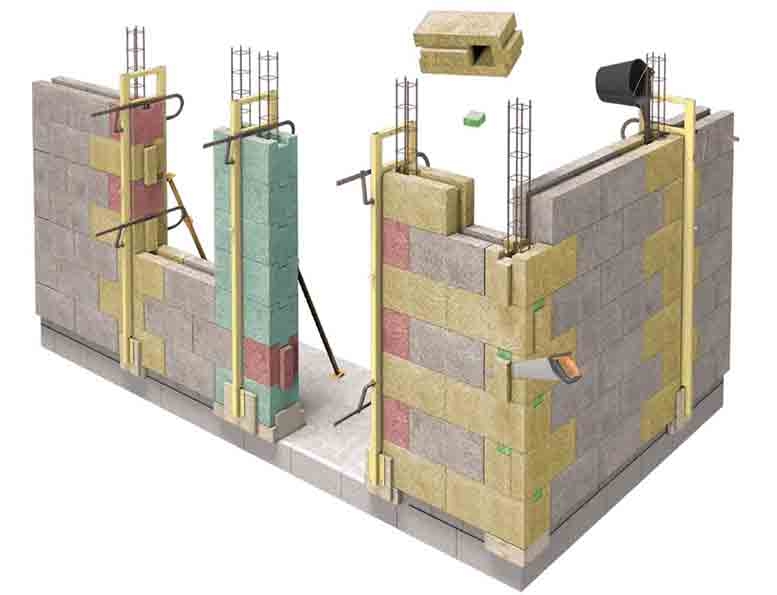

The HempBLOCK system employs post-and-beam framing of steel and concrete combined with interlocking pre-formed hempcrete blocks in a range of configurations that weigh about 40 lbs. each. The load-bearing structure is incorporated into the walling system during construction.

The system is suitable for the construction of single-family homes and small buildings up to two stories. The blocks can also be used to insulate existing buildings, providing a rating of up to R28, Tijssen said.

The company offers an in-house team of architects who help can develop basic building designs or work to advance existing plans by tailoring them to the HempBLOCK system.

What about certification?

U.S. hemp building enthusiasts have said getting hempcrete certified as a construction material is key to expanding the sector. Existing international standards could be used to support the case for certification in the U.S., as has already been done in other countries, Tijssen said.

“The lack of adoption of hempcrete by product users, such as builders, comes from their perceptions that green building products are usually not code compliant, are more expensive and require specialized training, skills and equipment,” said Tijssen, a veteran of traditional, more laborious infill hempcrete building in which the hempcrete is mixed on-site.

The products have been tested and accredited by organizations that are part of the International Laboratory Accreditation Cooperation (ILAC). The U.S. and Australia form part of this network and recognize the work that has been conducted by accredited testing authorities in other countries such as France.

Cost competitive

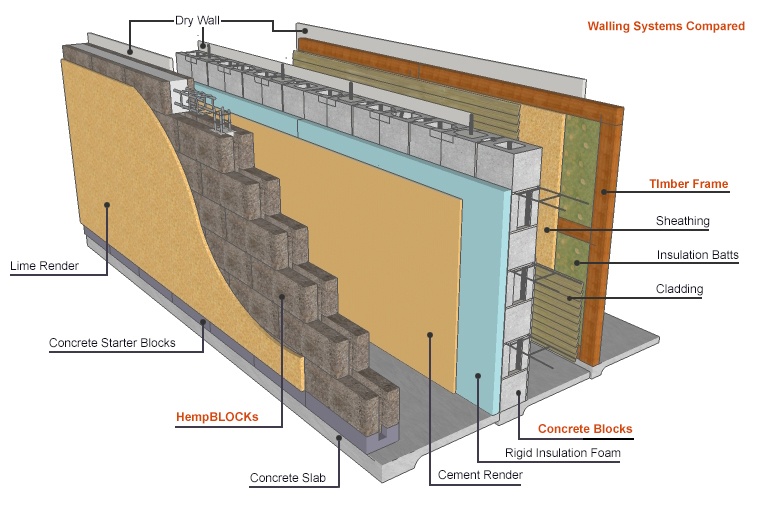

As for the cost, Tijssen said the company’s research showed that at $14 per square foot, building house walls with HempBLOCKs is cost competitive with traditional building materials and in many cases cheaper. “You only need 3 layers of materials rather 4 or 5 to achieve the same results,” Tijssen said.

HempBLOCKs are factory produced and arrive on-site, ready to use just like any block or brick. The interlocking blocks don’t require mortar jointing, and can be installed up to 70% faster than building with traditional materials. Also, no special equipment is required, and builders skilled in existing building practices can assemble HempBLOCK walls. “In fact, it requires more skills to build with traditional brick, concrete blocks or timber frames,” Tijssen said.

HempBLOCKs are formed on an automated production line that employs molds that are filled, vibrated and compacted. Once formed, the blocks are stacked for air drying. The patented system was designed and built by Biosys, which started production five years ago.

Speed of development

The nascent U.S. hemp construction market has so far failed to move beyond craft and demonstration status. But a number of fiber processing factories are going online across the country, primarily to supply a growing demand for hurd for animal bedding along with a few textile startups.

Tijssen said HempBLOCK’s U.S. and Australian units have commenced operations by importing products from their supplier, but the company has plans to set up manufacturing in the USA and Australia with its French partners.

“It will be commercially viable to manufacture blocks in the USA when market demand and the availability of hemp are at the level required to justify investing in a local production facility,” Tijssen said. “We believe that these conditions will be met within the next two years.”

Biosys France, the manufacturer of the HempBLOCK system, is part of Vieille Matériaux France, a key player in the European hempcrete sector, the most active in Europe. The Vicat group, a large French concern, owns the IP on the block design, construction system and the natural cement binder. Vicat works with Vieille Matériaux on product development and manufacturing.