A new study from a materials-science journal in China reports a low-temperature, chemical-free pre-treatment for industrial hemp fiber that could help textile manufacturers cut energy use and reduce wastewater while improving fiber quality.

Researchers from the College of Textiles and Clothing and the State Key Laboratory of Bio-fibers and Eco-textiles at Qingdao University paired a light-activated cleaning step with a mild enzyme wash, a combination that performed significantly better than the high-heat, caustic-alkali methods widely used in China and parts of South and Southeast Asia, according to a summary of the findings.

Pretreating hemp

Pre-treatment is the pre-decortication stage in hemp processing — the step that cleans and loosens the stalk’s natural gums before the fibers enter mechanical equipment. Lignin and pectin act like a natural glue that binds the bast to the woody core, making separation harder and increasing wear on decorticators.

Effective pre-treatment removes or softens these gums so decortication can run more efficiently, producing cleaner, higher-quality fiber for textile and composite applications.

Retting is the most common form of pre-treatment for hemp, relying on moisture and microbes to break down the natural gums that bind the fiber to the woody core. It can be done in several ways: field retting, where stalks are left on the ground to be softened by dew and weather; water retting, where bundles are submerged in ponds or tanks for faster microbial action; and enzymatic retting, which uses targeted enzymes under controlled conditions. All serve the same purpose—loosening the fiber before decortication—but vary in speed, cost, and environmental impact.

Cleaner inputs

The process tested in China runs at room-like temperatures and a neutral pH, avoiding the harsh conditions that can weaken hemp fiber. In testing, it removed most of the lignin and pectin while keeping the underlying cellulose structure intact. The authors say this balance is essential for producing softer, higher-value textiles without the environmental burden of traditional treatments.

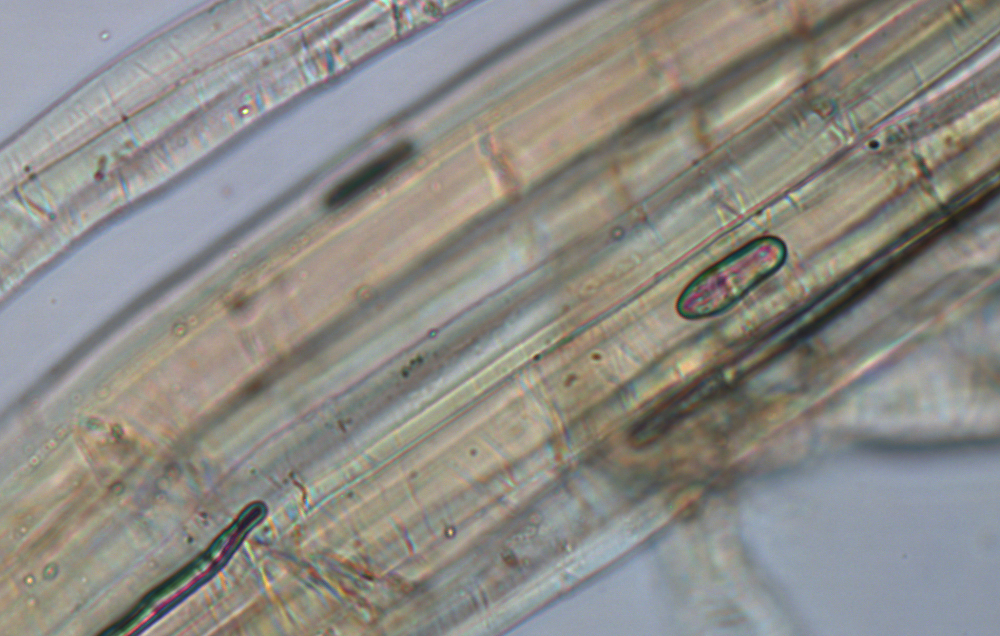

Close-up imaging and chemical analysis showed that the process breaks down the gummy material around the fibers and exposes cleaner bundles, a key requirement for textile-grade spinning and high-value composites.

How the process works

The first stage of the process uses light to help loosen the tough, bark-like material that holds hemp fibers together. The second stage applies a gentle enzyme wash that breaks down the natural gums even further. Working together, the two steps free the fibers more effectively than either method on its own, making them easier to clean and separate for textile use.

Researchers said the two mechanisms reinforce one another, with the combined process outperforming either treatment alone.

Preliminary estimates suggest the system could reduce energy consumption by 40–60% compared with conventional alkaline pretreatment. Because the method does not rely on caustic chemicals, it also generates significantly less wastewater, potentially making it suitable for decentralized fiber-processing sites where water treatment capacity is limited.

Commercial potential

If scalable, the technology could support the textile industry’s shift toward cleaner production and give hemp an edge as a low-carbon bast fiber. Cleaner pretreatment methods are critical for achieving the softness, fineness and spinnability required for high-value yarns — traits that remain difficult to achieve with today’s energy-intensive processes.

The study’s authors note that further pilot-scale work is needed to assess equipment requirements, reaction times, and the durability of the photocatalyst under continuous use.