“Our factory and farm yard looked like a graveyard of all kinds of agricultural machines,” remembers HempFlax CEO Mark Reinders.

Victims of an early flurry of trial and error harvesting and processing hemp fiber, the idle machinery was a reflection of the dream of HempFlax visionary Ben Dronkers, who founded the company in 1993.

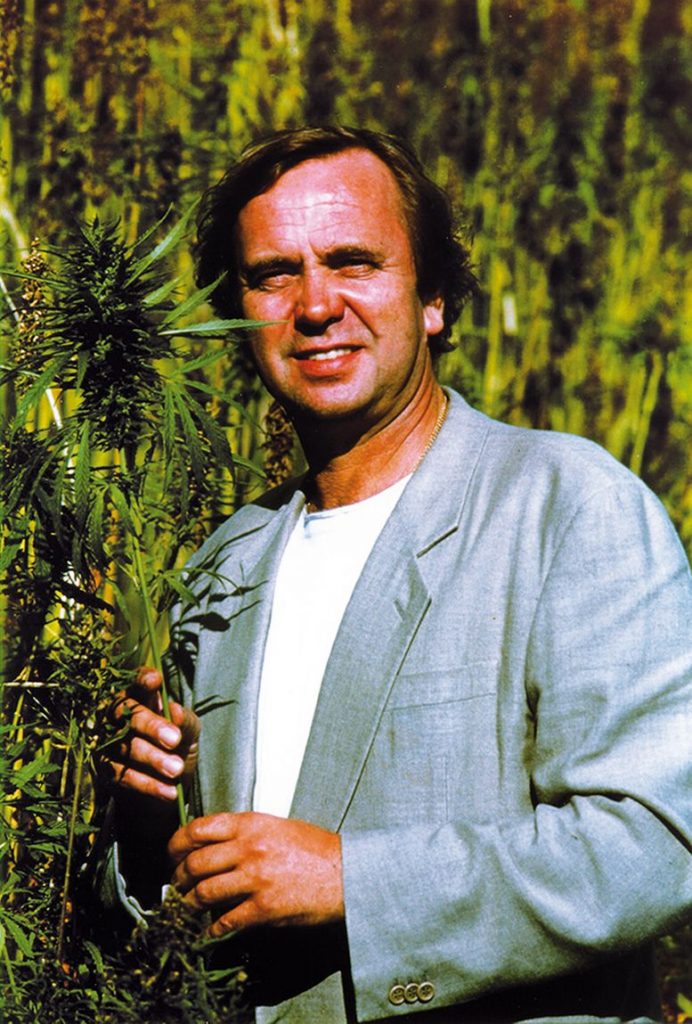

“Ben founded HempFlax mainly to prove to all the skeptics that hemp could be a modern industrial crop,” Reinders said. Dronkers had been active in the cannabis industry for decades, and he knew the extent to which hemp had been used for industrial purposes in the past, Reinders noted.

“We embrace and promote the philosophy of the circular economy.”

Mark Reinders, CEO, HempFlax BV

“When we started operations in the early ‘90s, nobody knew how to harvest or process hemp because the crop had been forbidden for 60 years,” Reinders recalled. As a result, no technological advancements for harvesting and turning hemp into products had been made for decades.

“We first tried to process hemp in a flax mill on a traditional flax scutching line (the genesis of “Flax” in the company’s name),” Reinders said. “Very soon we found out that hemp processing needed specialized technology” – technology robust enough to handle what’s generally considered to be the toughest of nature’s fibers.

Global icon

Fast forward to today and HempFlax has a corporate identity known to hemp stakeholders and enthusiasts all over the world. It is the very model of a 21st Century, international, vertically integrated hemp company working to exploit the entire plant for all its promise.

Through 25 years, HempFlax’s list of achievements is remarkable:

- From 140 hectares of Dutch hemp fields from its first planting in 1994, the company expanded into 2,600 ha in three countries by 2018.

- By 2009 HempFlax began widening its portfolio, first to textiles when it acquired a needle punch non-woven line suitable for hemp fibers.

- Through the years, HempFlax has established relationships with blue-chip automakers Mercedes, BMW, Jaguar, Bentley, Porsche, and Bugatti to whom it supplies interior car parts.

- In a major development for the industry, the company has advanced the hemp harvesting process via its Double Cut Combine, which debuted in 2014. Developed with giant U.S. farm implement maker John Deere, the technology features an upper header that catches leaves and flowers as a lower unit harvests the hemp stalks. HempFlax runs three of those machines in its own operations, has built and sold three others, and is sitting on an additional three orders due for delivery this year, according to Reinders.

- In 2015, the company opened a state-of-the-art decortication factory that added 40,000 metric tons of annual capacity to bring the company’s total potential to 55,000 tons.

- Other technology investments include development of controlled drying facilities that turn out super high-quality biomass, started in 2013; and a production line that makes pelletized hemp fiber for the injection molding and compounding industries started in 2016. HempFlax is a leading developer of new applications for hemp fibers in these sectors.

- Perhaps most significantly, HempFlax entered the CBD sector in 2013, and since that time has been adding downstream CO2-based processing for whole plant extracts that go into capsules and tinctures sold through Hempure, its white-label division.

Focus on sustainability

“Being a pioneer is hard and expensive work,” Reinders said looking back over the company’s two-and-a-half decades in business.

“Next to developing technology the company also needs to develop markets, and most of the times markets for the products are not there,” he said. “On the other hand without being able to supply significant volume of hemp products, it is impossible to build a market.”

The key, according to Reinders, is to capture the value of the whole crop. “Focusing on only one revenue stream from the crop makes you vulnerable to market developments,” he cautioned.

Through it all, HempFlax has always put sustainability front and center, emphasizing the role hemp can play in cleaning up the planet.

“We embrace and promote the philosophy of the circular economy,” an economic system aimed at minimising waste while maximizing raw materials, Reinders said.

“We do a lot to stimulate awareness of hemp’s possibilities among entrepreneurs around the world. In this way, we contribute to the sustainability of their companies too,” he added.

With plans to expand growing fields to 3,500 hectares by 2020, HempFlax is projecting demand will be strongly driven by the CBD sector.

“Although some said CBD was over-hyped, it now looks like it will be an accepted and widely used food supplement or additive. We think it can have the same position as vitamin C in the near future,” Reinders said.

He expects continuing developments beyond what he calls the current ‘Generation One’ CBD products now available.

“Continous developments on formulations and applications are necessary to further develop this market,” he said. To keep up with the pace of change, the company brought on board a nutraceutical professional, as it continues to explore disruptive extraction methods and technologies, according to Reinders.

Plastics & construction

Meanwhile, HempFlax will invest in developing hemp raw materials for such things as pellets for injection molding and hemp-based construction materials; the company is already making pre-fabricated roof panels, has orders for at least a couple pre-fab homes this year, and added a construction expert to staff to serve that division of the company.

“Our biggest dream is to replace cotton with hemp,” Reinders said of the company’s R&D into fabrics.

As for its international plans, Reinders said HempFlax has followed closely developments in the USA, which this year legalized hemp federally under the U.S. Farm Bill. “We think it is time to cross the ocean and are looking for the best opportunity to bring our knowhow and technology,” he said.

What’s next?

Though HempFlax has gotten big, the company has maintained the experimental, entrepreneurial drive that gave it life back in 1994 when that first crop went into the Dutch soil.

With decades of experience in hemp growing and processing among its key managers and a staff just as passionate and dedicated to hemp as Dronkers, Reinders believes HempFlax is well positioned in the firmament of the world’s iconic hemp brand names.

“Our many years in the business give the company a major competitive advantage in knowhow,” Reinders said. “Our horizon is broad, as is our approach to the whole plant. So we feel we’re positioned for whatever the next 25 years might bring.”

Hempflax through the years

- 1993: Founding of the company

- 1994: First crop of 140 ha planted, with initial processing in a flax mill

- 1996: Relocation of headquarters to Oude Pekela

- 2003: Acquisition of Venaro, a German processor; Acquisition of of Hempron, a German processor

- 2009: Takeover of Nafgo, German non-woven producer

- 2011: First ISO 9001 certification

- 2012: First crop grown in Romania

- 2014: Acquisition of 800 ha farmland in Romania; Debut of the Double Cut Harvester

- 2015: Opening of new Factory in Romania €10 million investment

- 2016: CEO Mark Reinders becomes President of EIHA ; Startup of fiber pellets production for injection molding and compounding; ISCC plus certified; HempFlax straw certified sustainable

- 2018: 2,600 ha hemp grown and harvested; ICCI implementation