As interest in hemp fiber applications grows, U.S. farm technology innovator Formation Ag says it is getting a growing number of inquiries about its mid-size hemp decortication units.

“There is a clear need for small and mid-size machines that can match the needs of the small and mid-size companies around the world. These are the farmers and smaller startup processors who make up the bulk of the market,” said Corbett Hefner, Vice President at the Colorado-based company.

“These giant facilities that many people are talking about aren’t the way to go,” said Hefner, who works regularly with stakeholders in different parts of the world. “When we talk about how to launch the industry with prospective customers, it’s pretty clear that mid-size, durable, expandable decorticating technology is what’s needed now,” he said.

Affordably priced

While industrial scale decortication technology can run in the millions of dollars, Formation Ag’s solutions begin at $139,000 (€120,000) for the company’s smaller model, the Fiber Track 660. That’s a justifiable investment for potential clients that Hefner said are interested in end products such as shivs for hempcrete, absorbents and animal bedding.

See the Fiber Track 660 in operation

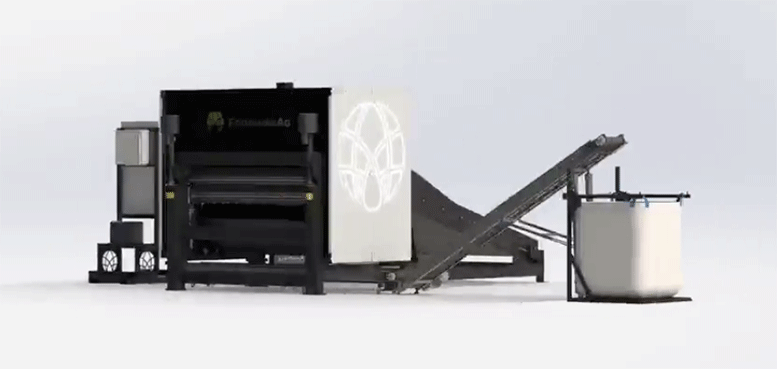

The Fiber Track 660 is a 6-roller unit that can turn out up to one ton of hemp material per hour, depending on genetics of the material and workspace organization, Hefner said. With a footprint of about 3×3 meters (10×10 feet), the machine is designed to handle straight hemp stalks, but is capable of processing un-oriented stems as well.

Modular design

Powered by four motors, the Fiber Track 660 generates up to 700 lbs of force per set of rollers, which are easy to access for removing jams and for cleaning. Additional guards can be removed without tools for access to gears, chains, and drives.

The decorticator can be operated with one worker to feed the machine and one to handle output. But the standard 60-in. (152 cm) input is wide enough that two workers can operate the in-feed side for maximum production.

Optional add-ons include in-feed and out-feed conveyors, a shaker table, a collection stand and technology to clean and sort the material. An end-to-end decortication system based on the 660 model runs about $230,000 (€198,000), and requires about 5,000 sq. ft. (465sq. m) of operational space, Hefner said.

Bigger model

Formation Ag is also offering a large scale decorticator, the Fiber Track Genesis, which can process as much as five tons of material per hour through a newly designed decortication system. Still in development, that machine is designed to handle un-oriented, baled material; the Genesis can handle round bales 65 in. (165 cm.) in diameter at this point, and will be able to process square bales in the near future. Hefner said the company also has pioneered technology to unwind bales that keeps the thickness of the feed consistent, a critical factor in maintaining quality output. In addition to turning out high quality hurd, Fiber Track Genesis also combs the hemp fiber to a semi-finished stage.

Both the Fiber Track 660 and the Genesis can be configured for mounting on semi-trailers for portability and operation in the field.

For now, Formation Ag is working on building relationships in Europe and South America in addition to its home base in North America, seeking input about customers’ needs as the company’s engineers continue to develop its decorticators to fit the future market. “We’re anxious to get more machines into people’s hands and identify what their new markets require. Once we understand the new requirements we can develop the technology. It’s the way we’re doing our part to help build – or re-build – this exciting new industry,” Hefner said.