Belgian hemp block maker IsoHemp said it has raised nearly €7 million to build a new high-tech factory, as the company sees demand rising for its pre-formed building materials.

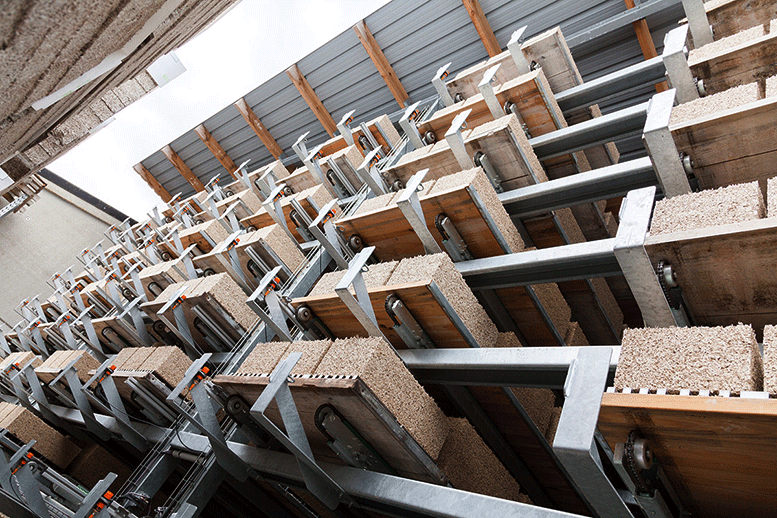

Planned for construction on a 2-hectare site, the factory is expected to go online in 2021. IsoHemp, which sources hemp and lime from local suppliers, said it will be able to raise production from 1 million to 5 million blocks per year to meet increasing demand. The company said growing enthusiasm for its products among builders and companies doing renovations has led to a doubling of its turnover year to year since startup eight years ago.

‘Industry 4.0’

The new factory “will be one of the most innovative in the eco-designed construction sector” and “part of the industry 4.0,” according to IsoHemp, employing Enterprise Resource Planning management software, robots and cobots to improve the eco-design logic which underlies the production process.

IsoHemp is responding to growing demand among clients doing renovations to make old buildings more energy efficient. “The challenges of energy renovation in the building sector are enormous, and bio-based solutions are progressing and gaining market share day by day,” IsoHemp said. “Solutions to insulate while respecting the environment do exist.” The renovation market makes up about half of IsoHemp’s sales.

Meanwhile, sales also are rising for new construction since IsoHemp launched Hempro, a modular system based on two sizes of blocks that can be supported by a column-beam skeleton, wood frame or load-bearing masonry of concrete, terracotta, aerated concrete or silico-calcareous aggregate.

The company estimates 30% of its sales are from materials used in new builds, with the remainder going into interior walls or custom applications in existing structures.

Sustainable solutions

Based in Fernelmont, Belgium, IsoHemp started making hemp building blocks by hand in 2012, gradually expanding production to reach output of 1 million units per year, while building out operations to establish representative offices in Netherlands and France, and further distribution in Germany, UK, Ireland, Italy, Israel and Spain. The company maintains extensive inventory, and is therefore able to react quickly to its customers’ orders.

A research and development department works continuously to improve performance of the all-natural materials that go into IsoHemp’s bricks and blocks.

‘Efficient solution’

IsoHemp, which recycles all of its manufacturing waste and recovers its production water, was recently identified as a “Solar Impulse Efficient Solution” under the Solar Impulse Foundation, which is dedicated to accelerating sustainable and profitable solutions to climate change. The Belgian foundation, created by aeronaut and aviator Bertrand Piccard, is supporting the development of 1,000 sustainable solutions for export while helping the Walloon region, where IsoHemp is located, to meet environmental objectives.