Researchers at a New York engineering school say they are developing siding insulated with industrial hemp for the remodeling of buildings to improve energy efficiency and reduce the carbon footprint of the built environment.

The research team, from Rensselaer Polytechnic Institute (RPI), Troy, NY, hopes to create a commercially viable, durable, and low-embodied-carbon insulated siding product in a three-year program financed with a $1.5 million grant from the Buildings Energy Efficiency Frontiers and Innovation Technologies (BENEFIT) program of the U.S. Department of Energy (DOE).

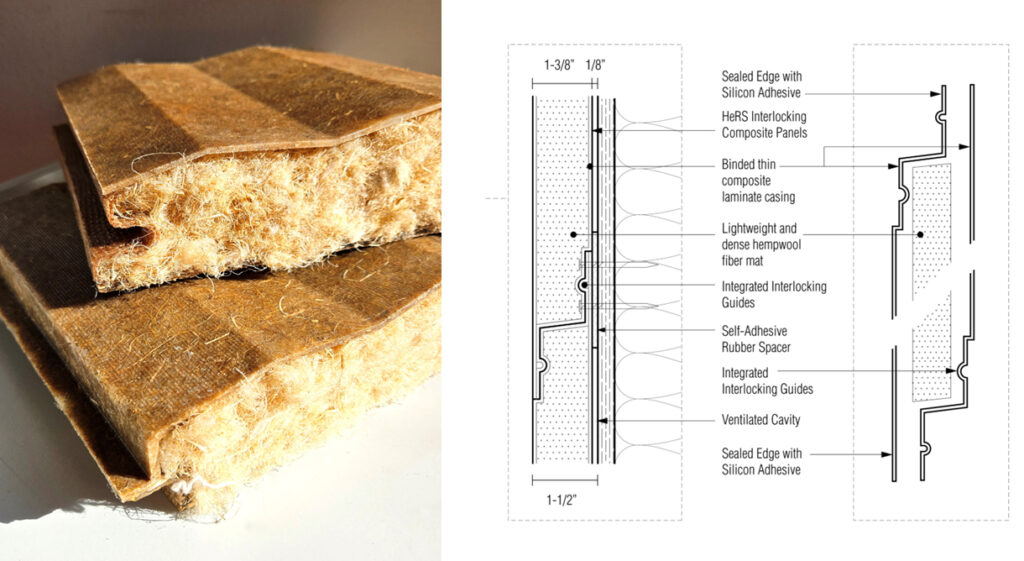

RPI faculty will work with industry partners in creating a Hemp Retrofit Structural Insulated Panel (HeRS) designed to lower heating and cooling costs for homeowners that is easy to install.

HeRS will use a dense mat of hemp wool fibers bonded with a recycled binder that has a similar form factor and attachment method to existing siding materials, according to an RPI press release. The finished product will have a minimum R-5 thermal performance to reduce heating, ventilation, and air conditioning energy use by 15%-25%.

Economic potential

“By utilizing this versatile and renewable crop in building materials, we can create a building retrofit product that will not only be beneficial for homeowners and the environment but also has the potential to jumpstart regional circular economies throughout the United States based on renewable materials,” said Alexandros Tsamis, associate director of the Center for Architecture, Science and Ecology at Rensselaer who is leading the project.

According to the DOE, residential buildings account for 60% of the total built surface area, with over two-thirds of those dwellings being single-family homes.

Part of the Seed to City hemp initiative at RPI, the hemp siding project stems from previous research from Tsamis and Daniel Walczyk, a professor of mechanical engineering, on the use of natural fibers as a resource for sustainable construction, such as hemp in rebar.

In addition to creating the design and manufacturing plans for the siding, the research team will conduct a viability study for supply chains that will demonstrate how quantities of hemp fiber produced in the United States can be effectively integrated into the production line of HeRS.

Industry partners

Industry partners on the project are Durasip, a Texas composites producer; Idaho-based hemp building materials maker Hempitecture; and Introba, Oakland, California, a designer of housing systems, according to the press release.

BENEFIT funding from the DOE supports the government-wide approach to the climate crisis by helping buildings to improve their energy efficiency and demand flexibility in a cost-effective and equitable manner. The winning projects were chosen through a competitive selection process that rigorously evaluated applications on their technical merit.

The award is issued through the DOE’s Office of Energy Efficiency and Renewable Energy, which has a mission to accelerate the research, development, demonstration, and deployment of technologies and solutions to transition to net-zero greenhouse gas emissions economy-wide by no later than 2050.