Customers from Poland, Luxembourg and Germany are the first to make commitments to purchase Henry’s Hemp Harvester (HHH), award-winning German technology specifically tailored to small and medium-sized farms.

Company founder and owner Heinrich Wieker said manufacturing partner Eilhauer, a specialized machine maker, is already welding custom components for a total of four units on order, with standard parts that will be used in the harvester now being sourced.

“These initial customers recognize the razor sharp tool we’ve created to solve their harvesting challenges,” said Wieker. “Attaining these customers is in keeping with our strategy to start with the European market, as that will allow us to closely track the performance of the machines in the field, and provide ongoing individual consultation.”

Wieker said he is still in talks with other Europe-based hemp farming operations about acquiring the harvester, and has seen interest from all over the world after starting sales at the end of last year.

Fits to small tractor

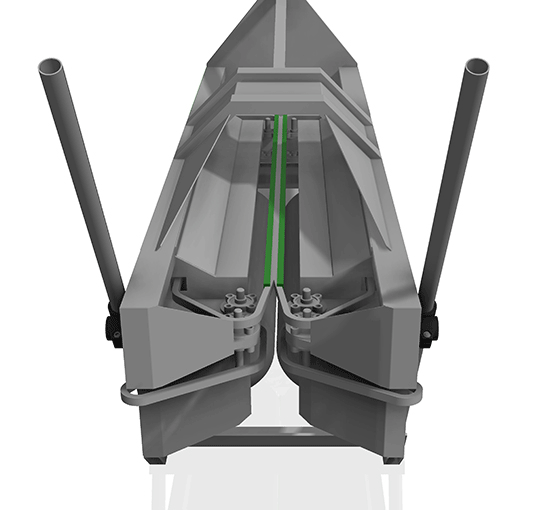

The HHH is a front-mounted attachment for harvesting industrial hemp flowers and stems, separately, in conventionally planted fields. Four years in research, development and production, the harvester can be driven by a small tractor, has an aluminum frame and rollers for weight reduction, and stainless steel components such as chains and other flower-contacting parts for food- and pharmacy-grade yields.

Wieker said Eilhauer completed the design of the HHH in just two and a half weeks, making only minor changes after strength and deformation simulations revealed what he termed “very satisfying results.” The company’s engineers are now completing detailed technical drawings of the harvester, with production of the HHH getting priority at Eilhauer’s facility in Langenhagen, Germany, in Lower Saxony, Wieker said.

The standard double-unit HHHarvester is designed to be efficient for conventionally planted outdoor hemp fields as small as 5 hectares (12.3 acres). Wieker said tests with the machine proved it can harvest 4-5 hectares (9.8-12.3 acres) per day. But the harvesting ensemble is modular, expandable up to six units that proportionally increase the harvest area. Prices range from €40,000 for a single unit with a cutting width of 70 cm (~28 inches) up to €190,000 for a six-unit ensemble that takes a cut of 420 cm (~14 ft). Total weight of each harvesting unit is about 250 kilograms (~550 lbs.). [Specifications]

North America in 2021

Looking ahead, Wieker said he aims to distribute manufacturing of the machine by outsourcing construction internationally. “One of our key goals for 2021 is to find a partner in North America who can manufacture the machine to our specifications and support us with sales,” said Wieker, who reports strong interest from farmers in the USA since the HHHarvester went on sale earlier this year, with preliminary partner discussions underway.

The HHHarvester was named winner of the European Industrial Hemp Association’s “Hemp Product of the Year” competition in June 2020.

Wieker also has developed an electrically-driven hemp bud stripper that can be used stationary in a barn or be transported on a trailer for operations in the field. That technology, which was honored at Expocáñamo, the annual Spanish cannabis expo in 2018, is expected to hit the market later this year.