Toronto-based CannaSystems Canada Inc. is offering its R-2 hemp decortication system to 10 initial customers under a collaborative program aimed at fine-tuning the technology while building close relationships with key partners.

Dave Greer, Vice President of Sales, said the company already signed agreements with customers in New Zealand and South Africa for the R-2, groundbreaking new technology that can be installed on a farm or trailer mounted for semi-mobile operation. The deals are through CannaSystems “Alliance” program, which offers special pricing – and special attention – to those customers who qualify.

Market sweet spot

Priced at $330,000 with processing capacity of 2 tons per hour, the R-2 hits something of a sweet spot in the market for large-scale decortication technology, which offers few reasonably priced options for handling industrial-scale loads.

“Most decortication machines on the market – and there are a relative few – run in the millions of dollars. While some small-scale solutions have been developed, steadily growing interest in hemp fiber production means future scalability is critical,” Greer said. The R-2 offers the necessary flexibility for future expansion of processing operations, and more.

CannaSystems designs, contract manufactures and sells equipment for production of industrial hemp biomaterials. Those materials, down the line, can be turned into a number of finished products – from textiles woven from the plant’s bast fibers, to bioplastics, building materials, fuel pellets, and biochar, one of the most promising potential uses of the hemp stem’s hard inner core (“hurd”).

4 ft. fibers

Importantly, bast output from the R-2 can result in fibers up to 4 ft. in length, an advantage in any secondary processing stage. “That’s a critical advantage, because when you look into the sectors that use hemp fibers, standards for length and other characteristics are still being developed,” Greer said. “With those fibers in 4 ft. lengths, they can be cut to size depending on customer requirements.”

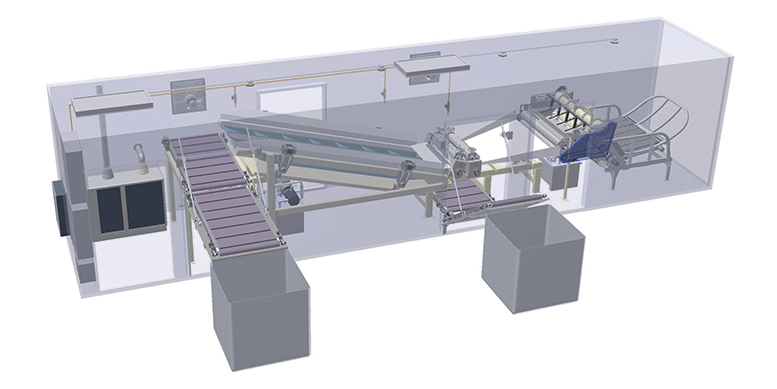

The R-2 system is built into a 40-foot “high cube” shipping container, providing a fully integrated unit with all critical functions: power, input, processing, throughput, a fire system, dust control and waste handling. The self-contained, semi-portable unit can run outdoors powered by diesel. Permanent installations require only a cement slab and an industrial electricity supply.

Alliance partnerships

To maximize the R-2’s operation, Greer said CannaSystems will follow its units out the door and work closely with those customers under its Alliance program, monitoring their experiences and the machines’ performance. Input from those initial partners will be used to make any needed refinements to the machine. Any upgrades made will be offered to all Alliance members at no cost.

“We have done extensive testing with our prototype and found that it works very well,” Greer said. “However, there will be situations not foreseen, given that we could not possibly test for every strain of seed or every planting or harvesting process.”

Alliance members also get dealer-priced discounts of 30% on their purchases, paying just $225,000, and receive continued dealer pricing for any future purchases. “This automatically puts our Alliance members in a good position to be partners in our global expansion,” Greer said.

Bringing IP together

Design of the R-2 decorticator, which has been six years in research and development, is based partly on processing machines built for other crops, such as banana, pineapple, sisal and palm. The design also incorporates patents on hemp processing technology from the mid-20th century which were updated with modern CAD design and material specifications.

“Advances made over the past 70 years are significant when it comes to building farm equipment to handle hemp crops,” Greer said. CannaSystems has exploited those advances through existing patents while developing intellectual property in house for new manufacturing and “green” processes for key markets.

The company built prototypes and full-scale machine heads last year and assembled and tested a complete full-scale R-2 system. After a round of upgrades and the addition of an integrated bale unwinder, the R-2 reached the commercial production stage, and can be fully functional upon delivery, Greer said.

Hitting ‘critical mass’

CannaSystems was founded in 2015 by cannabis industry veteran Bruce Ryan, Founder, and Ron Larson, CFO, a corporate finance executive who worked at PriceWaterhouse and ManuLife, and held the position of CFO for X-Prize and NASA rocket businesses.

The company has been self-financed through six years of research and development. Greer said early attempts to raise small amounts of seed money proved unsuccessful. While the company is in talks with potential investors and entertains qualified potential partners, CannaSystems has now reached a “critical mass,” Greer said, based on the technology’s readiness and eager, well-defined markets for fiber and hurd. That means CannaSystems will continue to develop as hemp farming and production grows around the world.