Researchers in the United Kingdom are working to advance the use of hemp and other natural fibers to replace polluting materials in conventional circuit boards.

Experts from Waterlooville-based Jiva Materials and the University of Portsmouth were recently awarded a government grant to further develop and commercialize the concept, which has also been studied in Germany and Sweden.

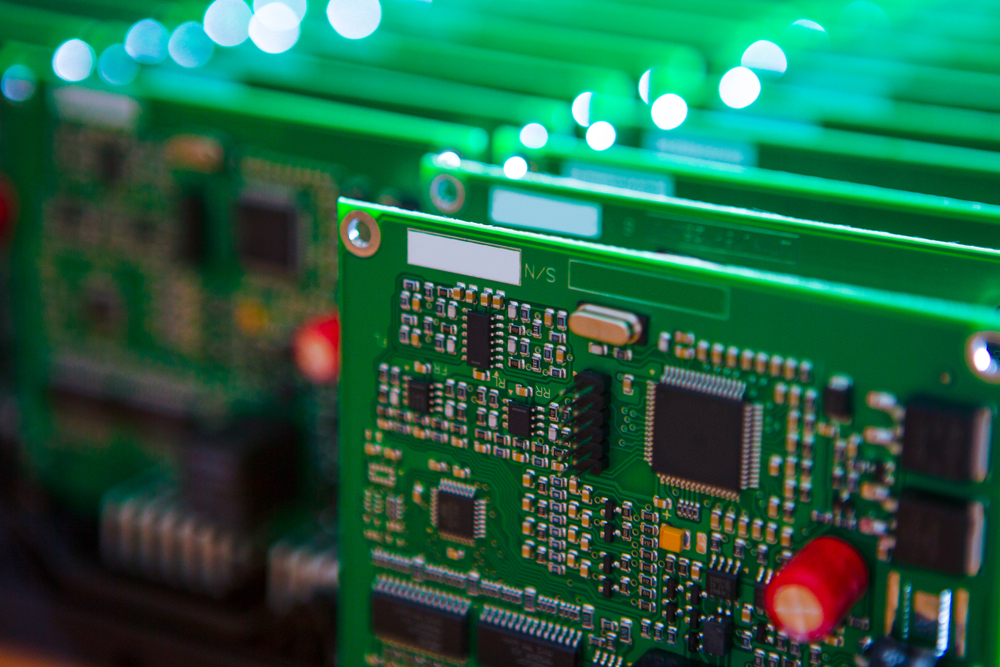

Printed Circuit Boards (PCBs), used in everything from pacemakers to rockets, are the ubiquitous hidden brains behind modern technology. Rigid laminates required for PCBs have been made using highly polluting glass fiber epoxy for more than 70 years.

At the end of their life cycle, less than 50% of the electronic waste from those boards is recyclable, and the gold, silver and platinum content is usually too little to recover.

The e-waste problem

“Electronics represent a growing waste problem globally,” Jiva said in a press release announcing the partnership with the university’s Advanced Polymers and Composites (APC) Research Group. “On average, each person in the world generates 7.5kg (16.5 lbs) of electronic waste every year. . . with PCBs believed to account for 8% of all e-waste.”

The alternative being developed by Jiva and the APC researchers is made by impregnating natural fibers with a water-soluble and halogen-free flame retardant, making the recovery of electronic components containing valuable materials more feasible when the PCBs are discarded.

Fully recyclable rigid PCB laminates based on natural fibers can have a 60% lower carbon footprint compared to glass-fiber and epoxy technologies, and can reduce the £8 billion ($10 billion) worth of critical minerals that go into UK landfills every year, Jiva said.

Fully compatible

The bio-based laminates can be fully compatible with existing processes such as acid/alkaline etching, electroplating, drilling, routing and curing required in PCB production, according to the researchers.

Jiva has already produced a water-soluble PCB from a flax-based composite which breaks down when immersed in hot water for a sustained period. The grant will allow the research team to continue its study of flax, and begin to explore the potential for hemp- and jute-based composites.

The APC Research Group at the University of Portsmouth is part of the School of Mechanical and Design, which focuses on applied research into sustainable composite materials and manufacturing through partnerships with industry.

‘Innovate UK’ funding

The funding is from a Knowledge Transfer Partnership (KTP) under “Innovate UK,” a government program that connects businesses with universities to pursue innovative initiatives.

In Germany, researchers at the Nagele Research Center of the Technical University of Munich have developed PCB laminates from bio-based thermoplastic reinforced with hemp and wood fibers. Also, Research Institutes of Sweden (RISE ) is working on a project to develop bio-based circuit boards using hemp and other natural fibers.