A North Dakota company has developed a building system based on inter-connecting pre-fabricated panels for the construction of single-story homes.

Homeland Hempcrete of Bismarck has entered into a proof-of-concept phase with a kit for a simple 150 sq. ft. structure now on the market, said Matt Marino, owner of the company.

“Once we show how the components fit together, and we’ve perfected the logistics, we can scale up both the sizes of the buildings and production,” Marino said.

Built-in frame

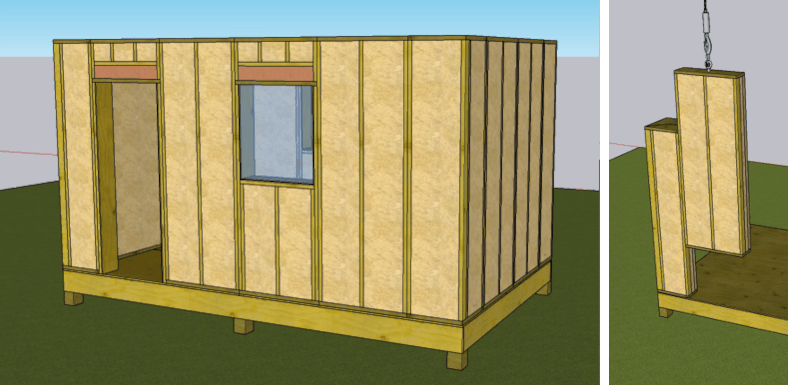

The modular system is based primarily on 3-ft by 8-ft wood frames that are lain flat and filled with a hempcrete mixture, then stored to cure for 30 days before being prepared for shipment to the building site. The panels, in thicknesses of 9 inches and 12 inches, can then be stood upright and connected, resulting in a double-stud, load-bearing skeleton.

Depending on thickness, each section weighs roughly 350 lbs. or 440 lbs., and can be handled manually by four persons, or set into place with a skid-steer loader or forklift, Marino said. The walls can be finished in a variety of ways immediately after they are installed. The foundation can be a concrete slab or wood pillar-and-beam.

“Our main goal was to simplify and speed up construction while making the kit system comparable in price to conventional on-site builds,” in which forms are put up around a frame and infilled with a wet hemp and lime mixture to form the walls, Marino said. He estimates the system reduces the time to put up the walls by 75% while eliminating the 45-day cure time required for traditional cast hempcrete buildings.

Stability in transport

Homeland has overcome the critical logistical challenge of transporting the pre-made panels, which can be fragile. Short moves with no breakage have been successful so far, and the company has a longer haul planned soon to further test the panels’ stability, Marino said.

The company is now offering a limited number of tiny structures comprising 16 panels, and will be hands-on in putting those buildings up as it refines the system. A modest size home would require roughly 50 panels which can be configured according to any design specifications for a one-story dwelling.

Marino said the company will eventually concentrate on simply producing the panels and other components to supply contract builders and do-it-yourselfers.

Homeland Hempcrete entered the market in 2019 offering traditional cast-in-place hempcrete construction, turning its attention to the development of the modular system beginning in 2021.